Digitale Transformation

Individuelle Lösungen

KI in Webanwendungen

UX/UI-Design

Cloud-Lösungen

IT-Integration

Digitale Transformation

Individuelle Lösungen

KI in Webanwendungen

UX/UI-Design

Cloud-Lösungen

IT-Integration

Nun, da Sie hier sind, entdecken Sie, warum wir die perfekte Wahl für Ihre Digitalisierung sind.

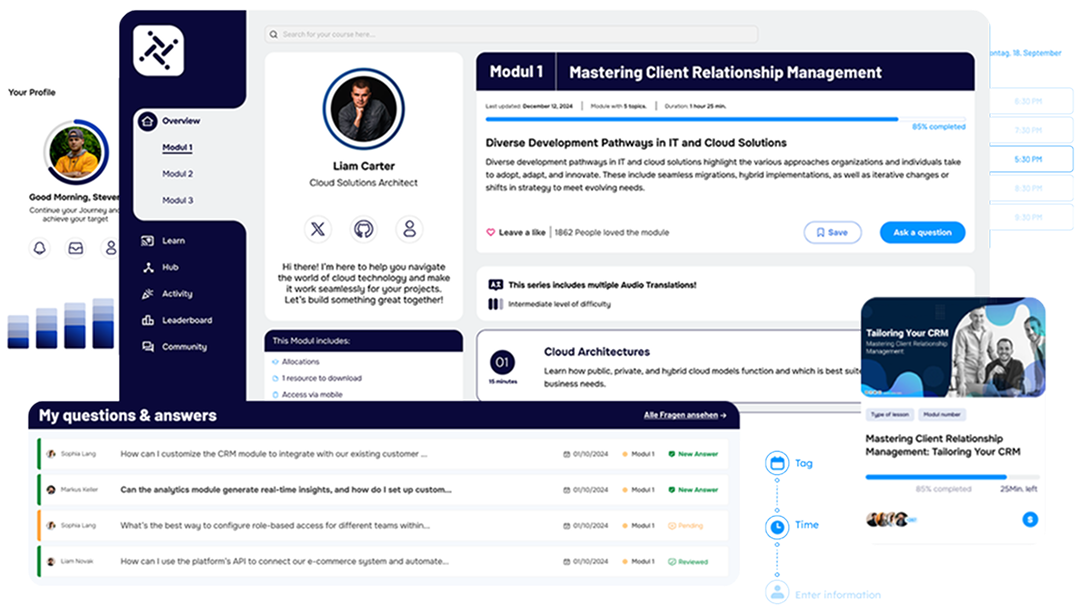

Jedes Projekt steht für unser Engagement, digitale Transformation durch kreative und funktionale Lösungen voranzutreiben. Wir schaffen Designs, die nicht nur inspirieren, sondern auch realen Mehrwert bieten und Ihre Geschäftsziele nachhaltig unterstützen.

Erschließen Sie das Potenzial Ihres Projekts mit uns!Kontaktieren Sie uns noch heute,um Ihre Reise zu beginnen!

Erfolgreiche digitale Lösungen entstehen nicht zufällig - sie sind das Ergebnis vertrauensvoller Zusammenarbeit, tiefem Verständnis für Geschäftsprozesse und kompromissloser Qualitätsansprüche.

Benutzerfreundlichkeit

Barrierefreiheit

Konsistenz

Ästhetik

Sicherheit

Flexibilität

Wiederverwendbarkeit

Leistung

Intuitivität

Testen

Automatisierung

Effizienz

Kontrast

Proportion

Robustheit

Zuverlässigkeit

Der Erfolg unserer Projekte wird durch enge Partnerschaften und eine vertrauensvolle Zusammenarbeit erreicht. Dieser partnerschaftliche Ansatz ermöglicht es uns, leistungsstarke Lösungen zu entwickeln, die direkt auf Kundenbedürfnisse abgestimmt sind. Gemeinsam erzielen wir herausragende Ergebnisse, die den langfristigen Erfolg sichern.

Bediente Branchen

Kundenbindungsrate

Erfolgreiche Projekte

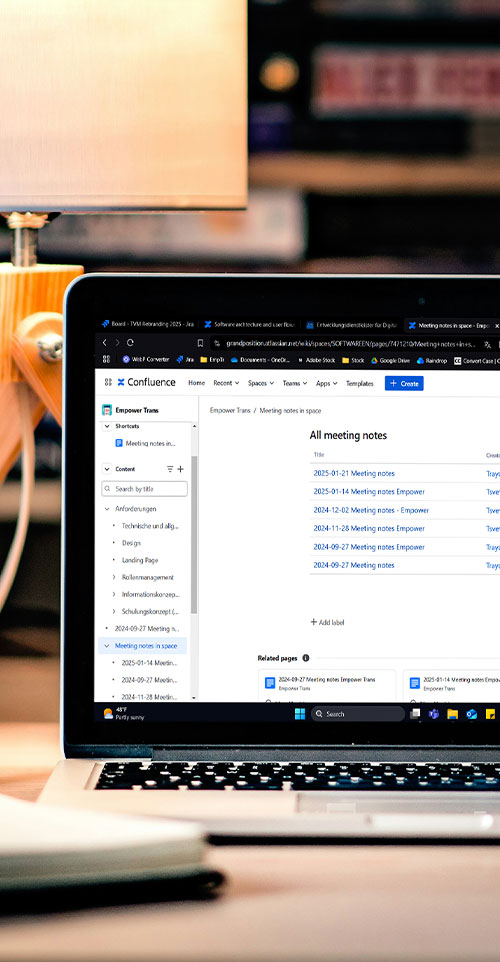

Jeder Kunde hat direkten Zugang zu unseren Projektmanagement- und Entwicklungstools.

CI / CD auf Staging- und Produktionsserver

Git

GitLab

GitHub

Git

GitLab

GitHub

Docker

CI / CD

Vercel

Docker

CI / CD

Vercel

Nginx

Apache

Windows Server

Linux Server

AWS

Azure

Google Cloud

Nginx

Apache

Windows Server

Linux Server

AWS

Azure

Google Cloud

TVM Engineering steht an der Spitze der Digitalisierung, ermöglicht KMUs Erfolg, transformiert die Automobilindustrie und treibt den Elektroniksektor mit IT-gestützten Innovationen voran, die den Markt neu definieren.

TVM Engineering steht an der Spitze der Digitalisierung, ermöglicht KMUs Erfolg, transformiert die Automobilindustrie und treibt den Elektroniksektor mit IT-gestützten Innovationen voran, die den Markt neu definieren.

Geschäftsführer

Dipl.-Ing. (TUM)

Geschäftsführer

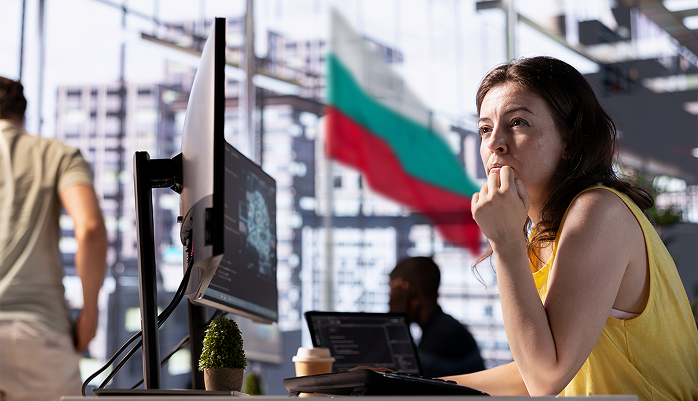

Bulgarien: Der aufsteigende Stern in Europas IT- und Softwarebranche

Überlegungen zu Nearshoring-Strategien für Unternehmen in der DACH-Region

Modularität und Spezialisierung: AUTOSAR

Warten Sie nicht - kontaktieren Sie uns und lassen Sie uns Ihre Vision mit unserer Expertise zum Leben erwecken!